|  |

|

|

|

|

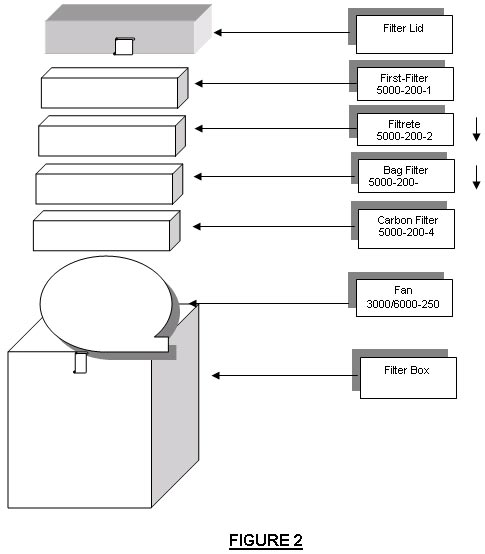

| a) | First Filter 5000-200-1 |

Specially constructed unidirectional filter media. |

| b) | Filtrete Pad 5000-200-2 |

Electrostatically activated unidirectional smoke particulate filter. |

| c) | Bag/Panel Filter 5000-200-3-BAG |

|

| d) | Carbon Filter 5000-200-4 |

The fume filter is replaced by undoing the latches holding the top of the Stand Alone Filtration unit. Remove the top to expose the filters, VACUUM AS YOU REMOVE. Gently remove the filters depositing them in a sealed plastic bag (NB: these are to be disposed of as hazardous waste). Seal the bag before replacing the filters with new product.

Recommended Filter Replacement is as follows:-

| Normal Working 1-2 Wave Single Shift |

High Rosin Fluxes, Lead Free Solders |

||

| or | No Clean/Low Solids Fluxes | 2 Shift Working | |

| First Filter | Cleaned Weekly | Replace before Week 2 | Replace Weekly |

| Filtrete/Smoke Filter | Cleaned Weekly | Replace before Week 4 | Replace before Week 2 |

| Bag/Panel Filter | Cleaned Weekly | Replace before Week 18 | Replace before Week 10 |

| Carbon Filter | Cleaned Weekly | Replace between 12-15 Months | Replace between 9-15 Months |

PLEASE REPLACE THE FILTERS WITHIN THESE SCHEDULES AS INCORRECTLY MAINTAINED FILTERS WILL BLOCK THE AIR FLOW TO THE FAN. THIS WILL CUT OUT ON ITS SAFETY PROTECTION GREATLY REDUCING THE FAN LIFE AND INVALIDATING WARRANTY.

These figures are advisory and will vary with adherence to cleaning and service schedules and on fluxes and processes in use at each location. No Clean Fluxes and Low Solids may extend the schedule above.

Each week please VACUUM each filter in the filter stack and INSIDE the EVS. This will greatly enhance the effectiveness and longevity of the filters and pay dividends in the long run.

ALL FILTERS ARE UNIDIRECTIONAL AND MUST BE FITTED IN ACCORDANCE WITH THE SERVICE MANUAL.

PLEASE REPLACE IN CORRECT ORDER AND ALIGNMENT

(Refer to Figure 2 - Page 3)

WARNING : When the filter is removed from the machine please remember to wear gloves and mask. Then it should be SEALED in a plastic bag and disposed of safely.

Fuse Replacement

The Stand Alone Filter has its own 2 amp fuse for electrical protection. This is housed in a small push out fuse holder located just above the on off switch

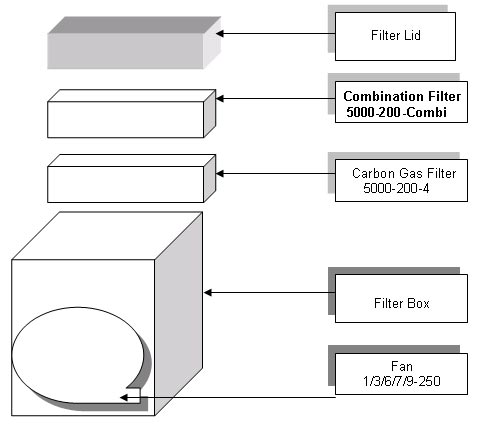

| a) | Combination Filter 5000-200-Combi |

Specially constructed HIGH FLOW COMBINATION PANEL FILTER with electrostatic properties. |

| b) | Carbon Filter 5000-200-4 |

|

FIGURE 3

Recommended Filter Replacement is as follows:-

| Normal Working 1-2 Wave Single Shift No Clean/Low Solids Fluxes |

High Rosin Fluxes, Lead Free Solders or 2 Shift Working |

||

| COMBI Filter |

Cleaned Weekly | Replace before Week 12 | Replace before Week 8 |

| Carbon Filter |

Cleaned Weekly | Replace between 9-12 Months | Replace between 8-12 Months |

PLEASE REPLACE THE FILTERS WITHIN THESE SCHEDULES AS INCORRECTLY MAINTAINED FILTERS WILL BLOCK THE AIR FLOW TO THE FAN. THIS WILL CUT OUT ON ITS SAFETY PROTECTION GREATLY REDUCING THE FAN LIFE AND INVALIDATING WARRANTY.

These figures are advisory and will vary with adherence to cleaning and service schedules and on fluxes and processes in use at each location. No Clean Fluxes and Low Solids may extend the schedule above.

EACH WEEK please VACUUM each filter in the filter stack and INSIDE the EVS. This will greatly enhance the effectiveness and longevity of the filters and pay dividends in the long run.

ALL FILTERS MUST BE FITTED IN ACCORDANCE WITH THE SERVICE MANUAL.

PLEASE REPLACE IN CORRECT ORDER (Refer to Figure 3 - Page 4)

WARNING : When the filter is removed from the machine please remember to wear gloves and mask. Then it should be SEALED in a plastic bag and disposed of safely.

Fuse Replacement

The Stand Alone Filter has its own 2 amp fuse for electrical protection. This is housed in a small push out fuse holder located just above the on off switch.

| web: www.solderrecovery.com |

email:

admin@evsinternational.com

|